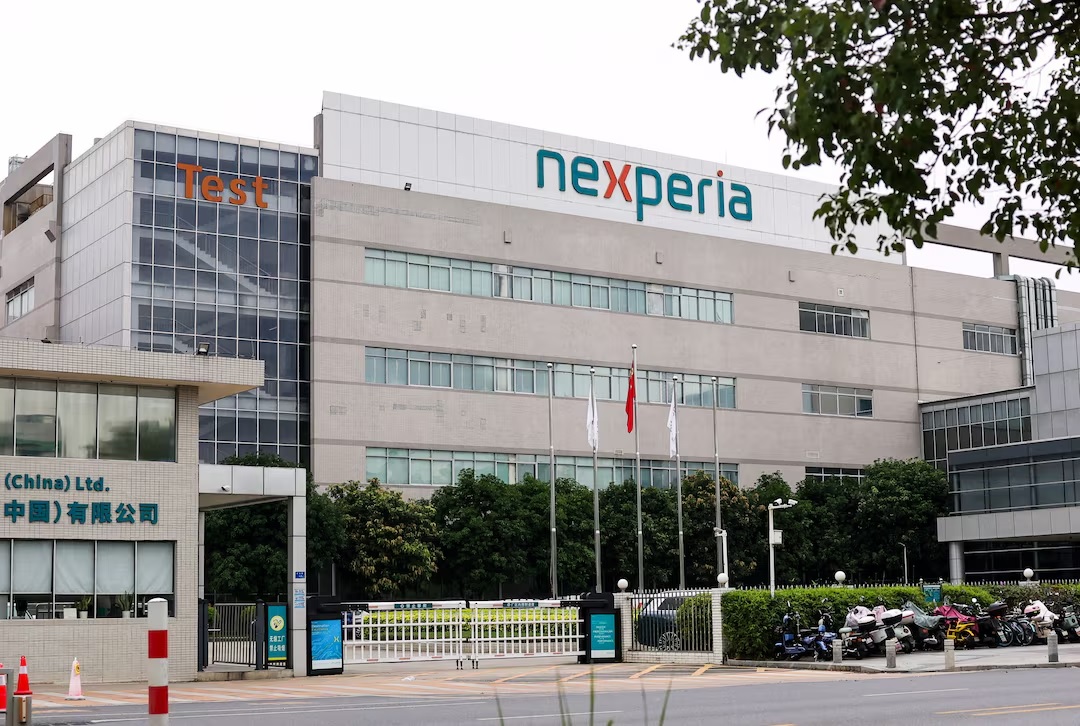

How the Nexperia chip crisis exposed auto supply-chain blind spots

Low-tech chips, high-stakes disruption

A modest-looking chip plant in China’s industrial south has become a global choke point for the auto industry, forcing manufacturers to confront how vulnerable they still are to “old” technology. The factory, run by Dutch chipmaker Nexperia in Dongguan, churns out low-cost semiconductors used in car brakes, electric windows and other basic systems. When political and regulatory tensions around the company escalated this year, supplies tightened and major automakers once again faced production cuts and furloughed workers.

European authorities had stepped in months earlier, when the Dutch government used special powers to take control of Nexperia on national-security grounds. Officials worried that sensitive semiconductor know-how could leak to the company’s Chinese owner. Beijing pushed back, and in response, exports of finished chips from the Dongguan plant were reportedly slowed or halted. For the auto sector, which had vowed never to repeat the chaos of the 2020–21 chip shortage, the episode was an uncomfortable reminder that even the cheapest components can shut down billion-euro factories.

Carmakers in Japan and Europe were among the first to feel the squeeze. Production lines at brands such as Nissan and Honda were forced to cut shifts or temporarily idle plants when deliveries of Nexperia parts fell short. Suppliers in Germany, including major systems makers, warned of overtime bans and shorter working hours as inventories ran down. Because the affected chips are simple, mature products, there are fewer alternative manufacturers with spare capacity, and qualifying new suppliers can take months. The result is that “pennies-per-piece” components can delay vehicles worth tens of thousands of dollars.

The crisis also highlights how geopolitics has become intertwined with the most mundane parts of the tech supply chain. Governments in Europe and North America have poured billions into advanced chip plants, focusing on cutting-edge processors for artificial intelligence and 5G. Far less attention has gone to older-generation lines that produce the power management chips, sensors and controllers embedded throughout modern cars. Analysts say the Nexperia case shows that any serious industrial strategy will have to cover the full mix of chips, not just the glamorous high-end segment.

For the auto industry, the lesson is sobering: diversifying suppliers on paper is not enough if most of them are still located in the same region or tied into the same geopolitical risks. Some manufacturers are now exploring long-term contracts with alternative foundries in Southeast Asia and Europe, even at higher prices, to avoid being caught short again. There is also renewed interest in building strategic stockpiles of key components, a practice many companies abandoned in the era of just-in-time logistics. How quickly those plans turn into concrete investments will determine whether the next shock is less painful than the last.